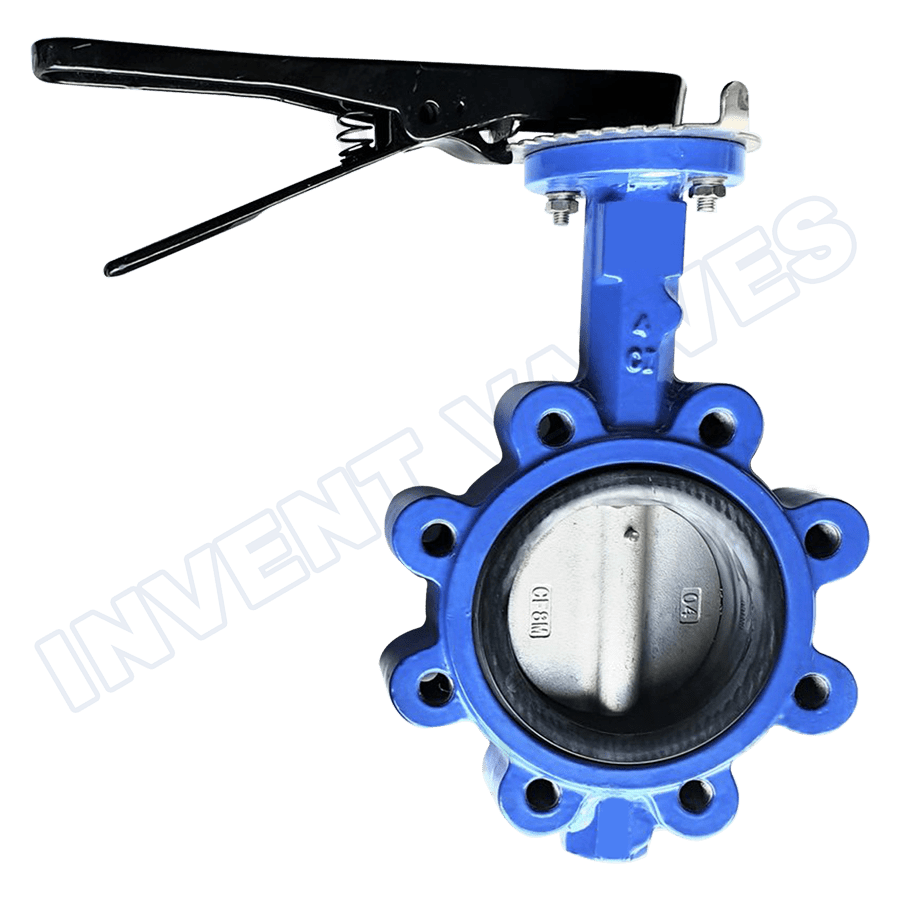

Lug Type Butterfly Valve

Butterfly Valves are having wide range of applications in Process Industries, Water Treatment, Sewage Plants, Power, Petrochemicals, Steel Plants and allied industries in a very large quantity. All type of Butterfly Valves is available with control type lever, Manual Gear, Pneumatic and Electric Actuators. We offer Butterfly Valves in cryogenic type of design. Our butterfly valves are made up of high quality raw material and are designed to actually optimize its efficiency and they provide long lasting tightness and are highly reliable. They are very easy and fast to open.

A Butterfly Valve is a flow regulating disc valve. According to the BVAA, a Butterfly Valve is “a Valve in which the obturator rotates about an axis at right angles to the direction of flow and, in the open position flow passes around the obturator.” Butterfly Valves Manufacturer operate similar to Ball Valves in their 90-degree rotation and allow for quick shutoff.

Butterfly valves are recently have been in trends due to their very thin profile between flanges that makes the valves lighter in weight and create very small instant footprint. And this design of the valve makes its cost lower if compared with other valves. There are various types of butterfly valves and each of them has very unique design and features, for more information contact us right now.

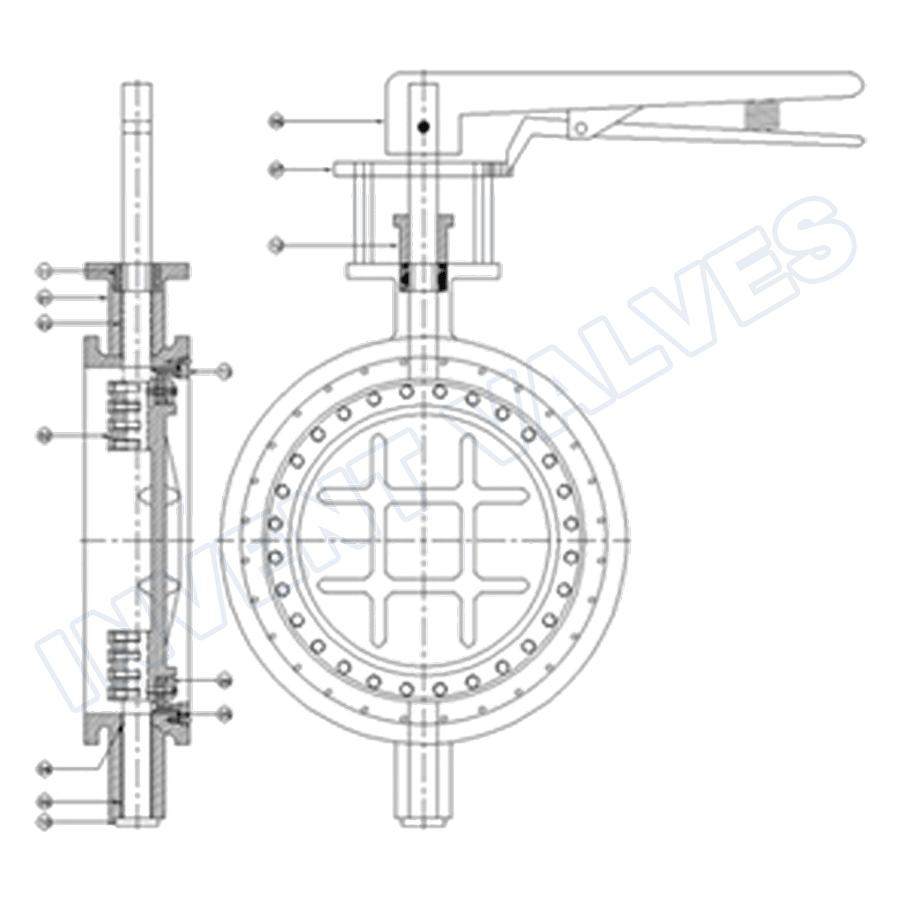

Technical Detail

Design Features:

- The unique Center Line seat and disc design insures positive valve sealing while maintaining low seating torque.

- All Center Line Butterfly Valve discs are precision machined to a half ball profile, providing a precise disc to seat relationship.

- Center Line’s cartridge style seat incorporates an elastomeric bonded to a phenol stabilizing ring, eliminating elastomeric movement and reducing seat tearing or fatiguing due to bunching.

- Center Line’s basic three bushing design completely isolates the valve shaft from the body, resulting in increased control of the valve disc, lower valve seating torque, and longer valve life.

- The Center Line cartridge seat has a much smaller mass of elastomeric than traditional boot seat designs, limiting seat swell and the accompanying variations in seating torque.

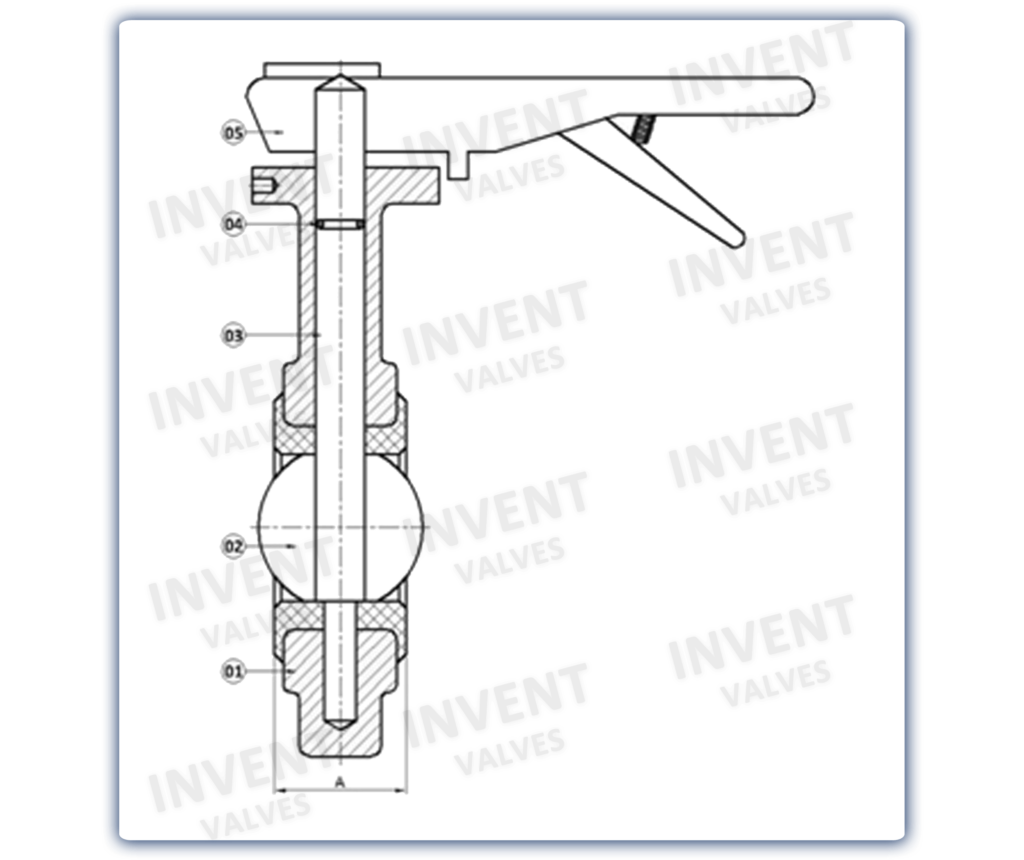

Materials Of Construction

| PART NO. | PART NAME | MATERIAL |

|---|---|---|

| 01 | Body | C.I./ C.S. / S.S.304 / S.S.316 with Integral Moulded EPDM/Viton Rubber Seat on Body |

| 02 | Disc | S.G. Iron (Black Epoxy Powder Coated & Nylon Coated) C.S. / S.S.304 / S.S.316 |

| 03 | Stem | AISI 410 / S.S.304 / S.S.316 |

| 04 | ‘O’ Ring | Nitrile / EPDM / Viton |

| 05 | Lever | M.S./ S.S./ Cast Iron |

Hyd. Test Pressure

| HYD. TEST PRESSURE | ||

|---|---|---|

| Pressure Rating | Body | Seat |

| PN-10 | 15 Kg/Cm² | 10 Kg/Cm² |

| PN-16 | 24 Kg/Cm² | 17.6 Kg/Cm² |

Seat

| EPDM |

-20°C to 120°C |

|---|---|

| NBR |

-10°C to 80°C |

| Hypalon |

-20°C to 135°C |

| Viton |

-18°C to 150°C |

| Silikon |

-20°C to 180°C |