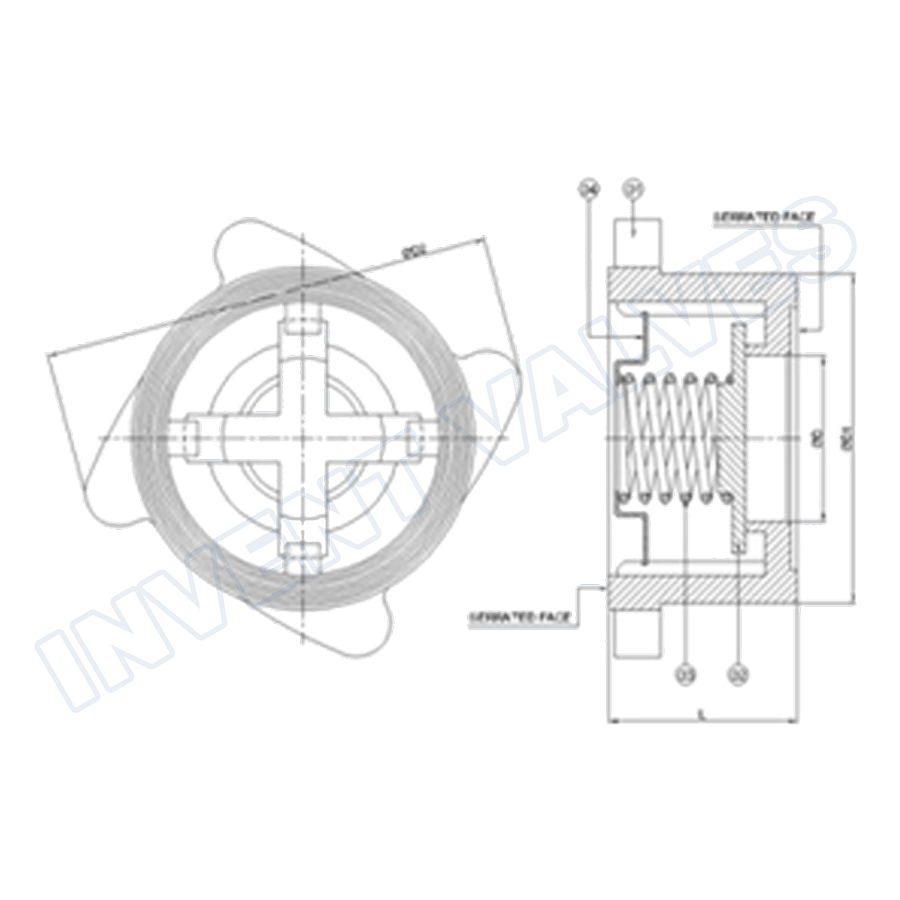

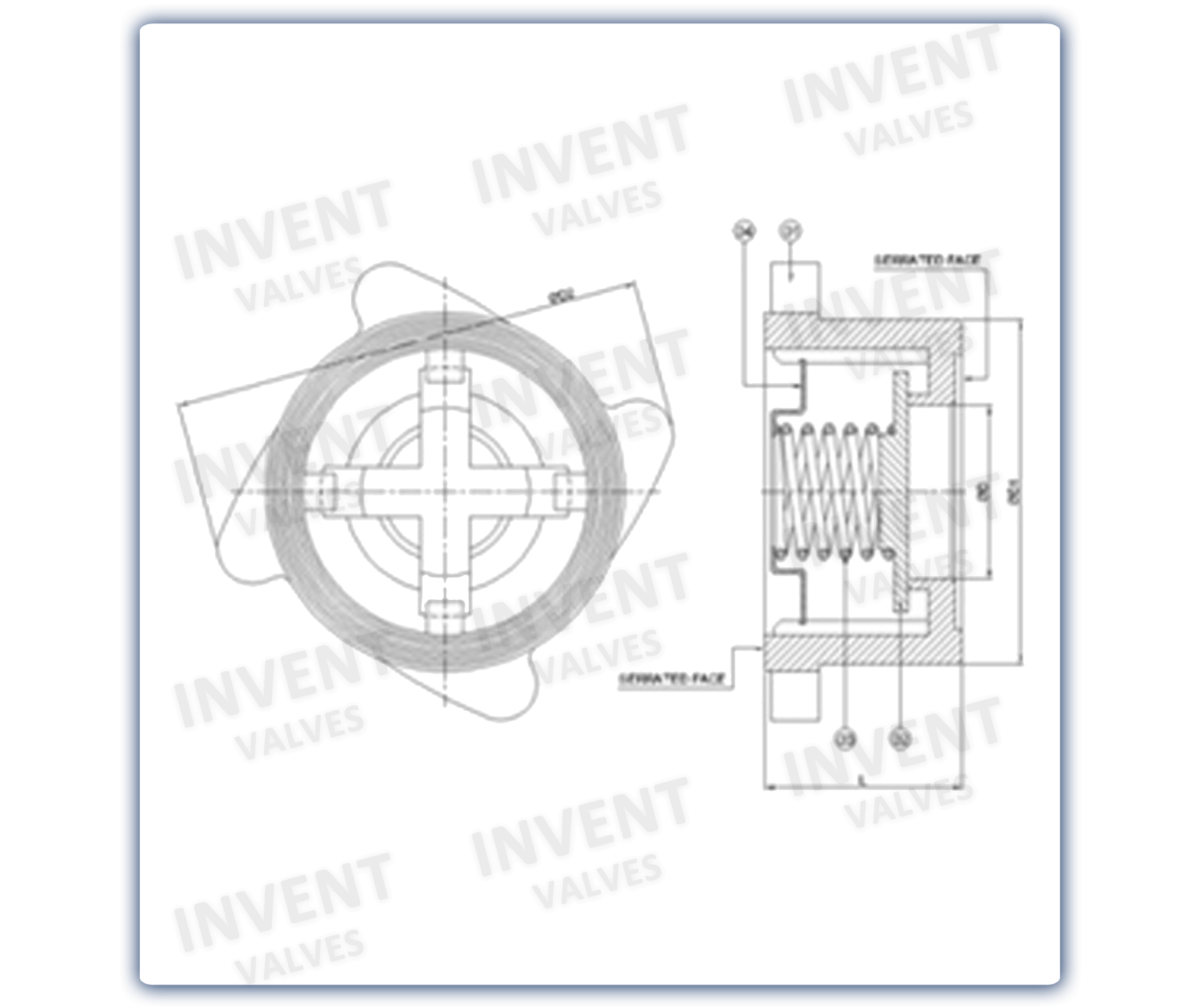

Non Slam Type Check Valve

The “INVENT” Ball Valves are economically priced and designed to last. These Valves provide exceptional performance in even the most stringent applications found in the Oil & Gas industry and other industries. We offer a wide range of elective seat and seal materials.

We are ManufacturingNon Slam Type Check Valves in Single Piece; Two-Piece & Three-Piece cast steel constructions. These Valves are manufactured to the highest possible quality standard. Many of our threaded and socket weld Ball Valves are manufactured according to the ASME B16.34 design standard. These valves provide the exceptional performance in even the most stringent applications found in the Oil & Gas industry and other industries. We manufacture high quality Trunnion mounted Ball Valve which are manufactured under, for more information contact us right now.

Features:

- Spring Closing arrangement for the prevention of reverse flow in pipe lines

- These Valves are general purpose valves that are stronger, lighter and smaller than conventional swing check valve and there before, less expensive to install and maintain

- Suitable for higher pressure / temperature (up to 400°C)

- It can be Mounted in any plane / direction

- Extremely low opening pressure

- Available Sizes 15mm to 150mm suitable for PN6 / PN-40 and ANSI 150/300

Pressure & Temperature Rating

- Tested as per API-598

- Maximum Body Design PN-40

- Maximum operating Pressure 40 Kg/Cm²

- Weight and dimensions are same for class 150 & class 300 Valves

- Valve are Self centering type

- zero leakage for soft seated valves.

- The maximum permissible leakage rate shall be 3 cubic centimeter per minute per inch of nominal pipe size for metal seated valves

- Design as per Manufacturing Standard

- Testing : as per API:598

- Maximum operating Temperature 300°C

- Maximum Cold Hydraulic Test Pressure 60Kg/Cm²

- Maximum Operating Temperature 50°C

Materials Of Construction

| PART NO. | PART NAME | A 105 | LF2 | LF3 | F304 | F316 | F11 | F22 |

|---|---|---|---|---|---|---|---|---|

| 01 | Body Bonnet | ASTM A105 | A350 Gr. LF2 | A350 Gr. LF3 | A 182 Gr. F304 | A 182 Gr. F316 | A 182 Gr. F11 | A 182 Gr. F22 |

| 02 | Disc | ASTM A105 | A350 Gr. LF2 | A350 Gr. LF3 | A 182 Gr. F304 | A 182 Gr. F316 | A 182 Gr. F11 | A 182 Gr. F22 |

| 03 | Seat Ring | A 182 Gr.F6a | A 182 Gr.F6a | A 182 Gr.F6a | A276-304 | A276-316 | A276-410 | A276-410 |

| 04 | Stem | A276-410 | A276-410 | A276-410 | A276-304 | A276-316 | A276-410 | A276-410 |

| 05 | Gland Flange | A 216 WCB | A 216 WCB | A 216 WCB | A351Gr.CF8 | A351Gr.CF8M | A 216 WCB | A 216 WCB |

| 06 | Bolts | A193 B7 | A320 L7 | A320 L7 | A193 B8 | A193 B8 | A193 B16 | A193 B16 |

| 07 | Nuts | A193 B7 | A320 L7 | A320 L7 | A193 B8 | A193 B8 | A193 B16 | A193 B16 |

| 08 | Packing | Graphoil Rings | ||||||

| 09 | Gasket | S.S.304 / S.S.316 Spiral wound Gasket with Grafoil Filler | ||||||

| 10 | Hand Wheel | Ductile or Malleable Iron | ||||||

Materials Of Construction

| PART NO. | PART NAME | CF8 | CF8M | F304 | F316 | F304L | F316L |

|---|---|---|---|---|---|---|---|

| 01 | Body | ASTM A 351 Gr. CF8 | A 351 CF8M | ASTM A 182 Gr. F304 | ASTM A 182 Gr. F316 | ASTM A 182 Gr. F304L | ASTM A 182 Gr. F316L |

| 02 | Disc | ASTM A 351 Gr. CF8 | A 351 CF8M | ASTM A 182 Gr. F304 | ASTM A 182 Gr. F316 | ASTM A 182 Gr. F304L | ASTM A 182 Gr. F316L |

| 03 | Seat Ring | S.S.304 / S.S.316 (Inconal) | |||||

| 04 | Spring Washer | AISI 304 / AISI 316 | |||||

Primary Service Rating & Test Pressure

| PRIMARY SERVICE RATING & TEST PRESSURE | ||||

|---|---|---|---|---|

| Class | Working Pressure | Hydraulic Test Pressure | ||

| Body | Seat | Temp. | ||

| PN 40 | 40 Kg/Cm² | 77 Kg/Cm² | 56 Kg/Cm² | 300°C |